FRP Pole Manufacturing Process

FRP poles are made through a pultrusion process that involves fiber rolls and resin. This creates a strong and durable pole that boasts impressive physical, chemical, and mechanical properties

Raw Materials

Fiber Roving

Unsaturated Polyester Resin

Fiber Sheet Rolling

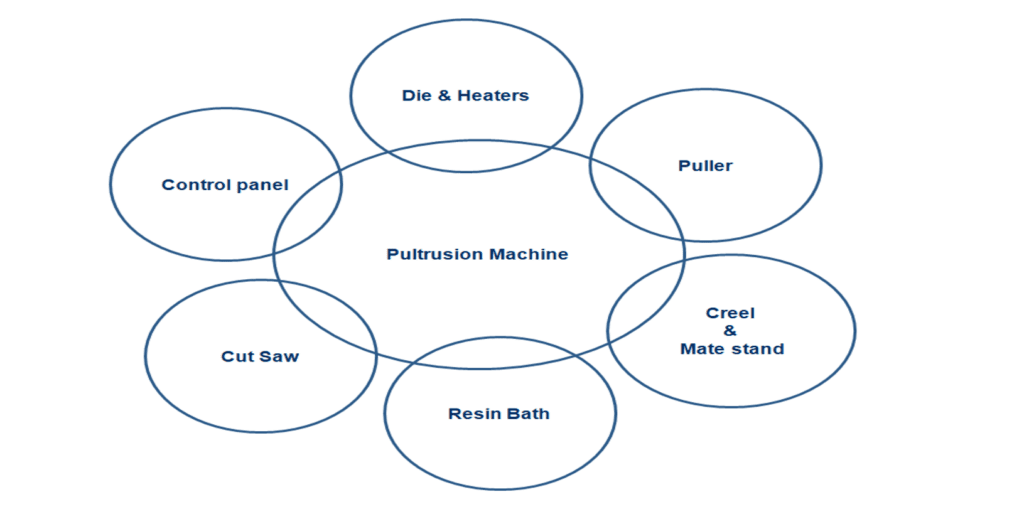

The Pultrusion Process

Heated Die

During pultrusion, the resin and fibers are pulled through a heated die. This shapes the pole and activates the resin to harden.

Pulling Device

A pulling device pulls the fibers through the die at a constant speed. This helps create a uniform pole with the desired properties.

Cut Off Process

A cut off process is used to trim the pole to the correct length. This completes the pultrusion process.

The Pultrusion Machine

Physical Properties of FRP Poles

1 Lightweight

FRP poles are 80% lighter than steel poles.

2 Corrosion Resistance

They are resistant to corrosion and do not rust. This makes them ideal for outdoor use.

3 UV Resistant

FRP poles can withstand UV radiation without degradation.

4 Impressive Strength

Despite being lightweight, they have incredible strength and rigidity, making them ideal for high load applications.

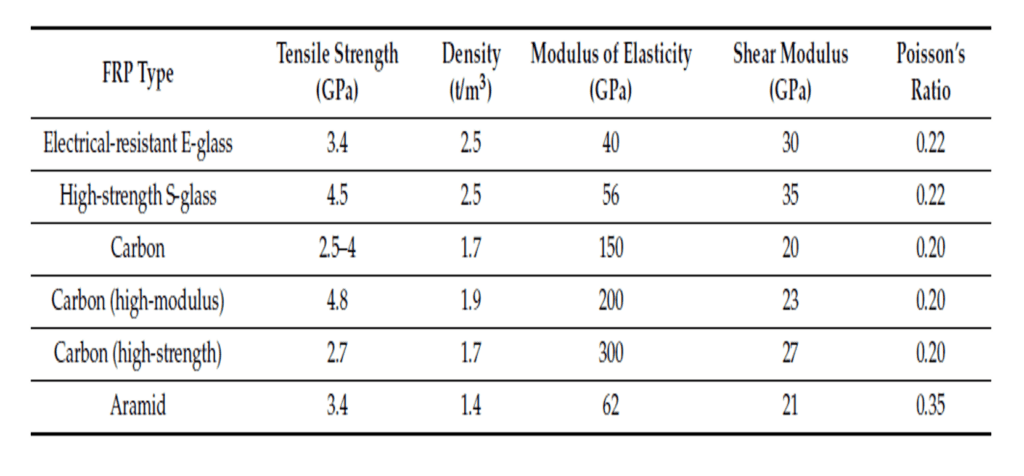

Physical and Mechanical Properties of FRP Poles

Samples of FRP Poles

Mechanical Properties of FRP Poles

1

Flexibility

2

Thermal Stability

3

Vibration Resistance

Advantages of FRP Poles

Environmentally Friendly

They are eco-friendly and can be easily recycled at the end of their lifespan.

Cost-Effective

Durable

FRP poles are long-lasting and have a lifespan of over 50 years.

Applications of FRP Poles

Utility Poles

Street Lighting